Why does a 30-day supply of generic lisinopril cost $4 at Walmart while the brand-name version, Zestril, runs over $100? It’s not magic. It’s not fraud. It’s manufacturing cost analysis - and the numbers don’t lie.

The Hidden Math Behind Generic Drugs

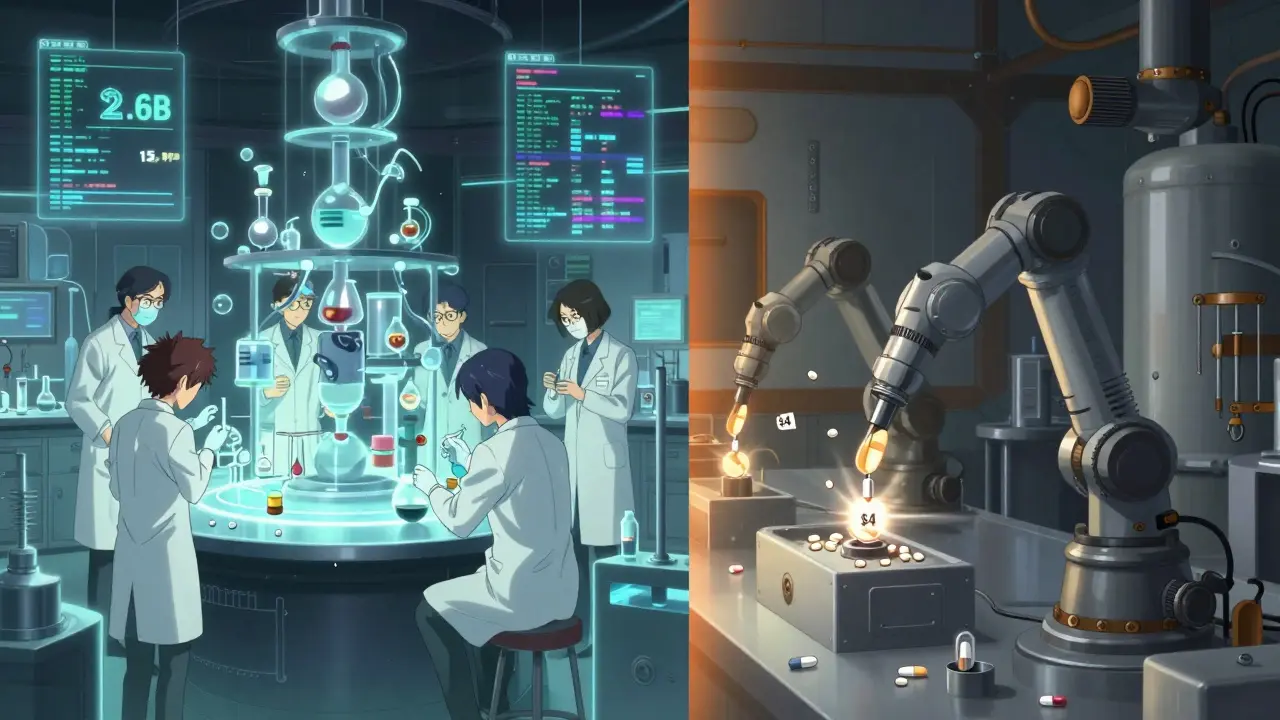

Generic drugs aren’t cheaper because they’re lower quality. They’re cheaper because they don’t carry the same weight of upfront costs. When a pharmaceutical company invents a new drug, it spends 10 to 15 years and about $2.6 billion on research, clinical trials, and regulatory filings. That’s not a guess - it’s from the Tufts Center for the Study of Drug Development. That money has to be recovered, and it shows up in the price tag. Generic manufacturers skip all of that. They don’t need to prove the drug works from scratch. They just need to prove it works the same way - bioequivalence. That’s it. The FDA lets them file an Abbreviated New Drug Application (ANDA), which costs between $2 million and $5 million and takes about 36 months to approve. Compare that to the $2.6 billion and 12-year timeline for a new drug. That’s a 99% drop in development cost.Where the Money Actually Goes

Let’s break down what’s inside a generic pill’s cost. It’s not just the active ingredient. There are four main pieces:- Active Pharmaceutical Ingredients (API): This is the actual medicine. It makes up the biggest chunk of cost - sometimes over half. But here’s the twist: API prices swing wildly. If a factory in China shuts down for environmental reasons, or a key chemical gets taxed, the price of the API can jump 20-30% in a year. That’s why some generics spike in price unexpectedly.

- Excipients: These are the fillers, binders, and coatings that make the pill hold together and be swallowed. They’re cheap, but they add up in volume. Think of them as the scaffolding around the medicine.

- Quality assurance: Every batch has to be tested. Every machine has to be calibrated. Every warehouse has to meet FDA standards. This isn’t optional. It’s not a luxury. It’s the cost of staying in business.

- Packaging: Blister packs, bottles, labels, child-resistant caps - all of it. It’s not glamorous, but it’s necessary. And it’s where a lot of savings happen through automation.

According to Boston Consulting Group’s analysis of 15 major generic makers, only 30% of the total production cost goes into the actual manufacturing process. Another 4% goes to supply chain logistics. The rest? Compliance, labor, overhead. And here’s the key: the more you make, the cheaper each pill becomes.

Economies of Scale: The Real Power Move

This is where generics crush branded drugs. When you produce 10 million pills a year, your cost per pill is high. But when you ramp up to 100 million? It drops by 18%. Double it again to 200 million? Another 18% off. That’s the learning curve - and it’s brutal for small players. The effect is even sharper when you focus on one specific pill. If you make 10 million units of a single drug - say, metformin - your cost per unit drops 45% compared to making 5 million units of five different drugs. That’s why generic companies specialize. They don’t make a little of everything. They make a lot of one thing. And they make it in one factory, on one line, with one team. That’s why you see the same few names over and over: Teva, Sandoz, Mylan, Cipla. They’ve scaled. They’ve optimized. They’ve cut waste. They’ve automated. And they’ve done it with margins so thin that a 1% improvement in efficiency can mean the difference between profit and bankruptcy, as Dr. James Robinson from UC Berkeley put it.

Why Brand Drugs Still Dominate Spending

Here’s the paradox: generics make up 90% of all prescriptions filled in the U.S. - that’s over 8.9 billion pills a year. But they only account for 15.8% of total drug spending. That means the other 84.2% of money is going to less than 10% of prescriptions - the branded ones. Why? Because brand drugs charge more. A lot more. Take cetirizine, the allergy drug. The generic version costs pennies. The brand, Zyrtec, costs 41% more per patient. Fluoxetine (Prozac)? 33% more. Alprazolam (Xanax)? 31% more. These aren’t small differences. They’re massive. And here’s the kicker: sometimes, the same company that makes the brand also makes the generic. But they price them differently. Retailers get a 25-30% margin on the brand. On the generic? Sometimes 200% to over 1,000%. That’s not a typo. It’s a perverse incentive. Pharmacies make more money selling the cheap generic than the expensive brand. But the system still pushes the brand because that’s what doctors are used to prescribing.Where Generics Struggle

Not all drugs are easy to copy. Simple pills? Easy. Inhalers? Hard. Injectables? Even harder. Why? Because they’re not just about chemistry. They’re about engineering. Take an asthma inhaler. It’s not just the drug. It’s the propellant, the valve, the spray pattern, the dose consistency. Replicating that isn’t just about matching the active ingredient. It’s about matching the delivery system. That requires expensive equipment, specialized labs, and years of testing. That’s why there are fewer generic inhalers - and why they’re more expensive than your average tablet. Same with complex biologics. These are drugs made from living cells. They’re huge, fragile molecules. Making a copy - called a biosimilar - is like cloning a snowflake. It’s possible, but it costs $100 million to $250 million. Still way cheaper than developing a new biologic, but not as cheap as making a generic aspirin.The Bigger Picture: Savings and Risks

The savings are staggering. The IQVIA Institute estimates that from 2023 to 2027, generic drugs will save the U.S. healthcare system $1.7 trillion. That’s more than the entire GDP of Switzerland. But there’s a cost. When margins are this tight, companies cut corners. And when a factory shuts down - because of a fire, a regulatory issue, or a labor strike - shortages happen. In 2022, there were 350 active drug shortages in the U.S., many tied to generic manufacturing. Dr. Aaron Kesselheim from Harvard Medical School points out that the pressure to keep prices low has made the supply chain brittle. The FDA is trying to fix it. Their 2023 Generic Drug User Fee Amendments (GDUFA III) are adding $1.1 billion over five years to speed up approvals. That should cut approval times from 40 months to 24. And automation? That’s the next big wave. Continuous manufacturing - where pills are made in one unbroken line instead of batch by batch - could cut production costs by another 20-25% by 2027. But there’s a new threat: geopolitics. Right now, 80% of the world’s API comes from China and India. If trade tensions rise, or if countries start demanding local production, costs could jump 5-8% overnight. That’s not a distant risk. It’s already happening.

What This Means for You

If you’re paying for prescriptions, ask for the generic. Always. It’s not a compromise. It’s the same medicine, just without the marketing, the R&D, and the profit margin. If you’re a patient on long-term medication - statins, blood pressure pills, antidepressants - you’re probably already on a generic. And you’re saving thousands a year without even realizing it. The system isn’t perfect. It’s messy. It’s pressured. But when it works - and it usually does - it’s one of the most efficient parts of modern healthcare. A $4 pill that saves you from a $100 hospital visit? That’s not just cheap. That’s smart.What’s Next for Generic Drugs

The future isn’t about making more generics. It’s about making them better. Faster. More reliable. Biosimilars are the next frontier. They’re not exact copies, but they’re close enough to cut costs by 15-30%. And as more biologics lose patent protection - like Humira and Enbrel - we’ll see this model expand. Manufacturers are also moving toward vertical integration. Some are buying their own API plants. Others are building their own packaging lines. The goal? Reduce dependence on outside suppliers. Reduce risk. Reduce cost. And then there’s policy. The Inflation Reduction Act lets Medicare negotiate drug prices. That could push generic prices down another 10-15%. It’s not a threat to generics - it’s a signal. The system is finally aligning incentives: pay for results, not hype.Final Thought: Cheap Doesn’t Mean Bad

We’ve been conditioned to think expensive = better. That’s true for cars, phones, and designer clothes. But in medicine? Not always. A generic drug isn’t a bargain bin product. It’s the result of decades of science, regulation, and ruthless efficiency. It’s the medicine that lets millions of people afford their treatments. It’s the reason someone in rural Alabama can take their blood pressure pill every day - and live. The real question isn’t why generics are cheaper. It’s why we ever thought branded drugs were worth the price.Are generic drugs as effective as brand-name drugs?

Yes. The FDA requires generics to have the same active ingredient, strength, dosage form, and route of administration as the brand-name drug. They must also prove bioequivalence - meaning they work the same way in the body. Studies show no meaningful difference in effectiveness or safety between generics and their brand-name equivalents.

Why do some generic drugs cost more than others?

Cost varies based on production volume, number of competitors, and the complexity of the drug. Simple pills like metformin have dozens of makers, so prices stay low. Drugs with fewer manufacturers or complex delivery systems - like inhalers or injectables - cost more. Also, if the active ingredient’s raw materials become scarce, prices can spike.

Can I trust generic drugs made overseas?

Yes, if they’re sold in the U.S. All generic drugs sold here, no matter where they’re made, must meet FDA standards. The FDA inspects foreign manufacturing plants just like domestic ones. In fact, over 80% of generic drugs sold in the U.S. are made overseas - mostly in India and China - and the FDA has found no consistent pattern of lower quality.

Why do pharmacies sometimes push brand-name drugs?

Sometimes, it’s because the pharmacy makes more profit on the brand - especially if the same company makes both the brand and generic versions. Retailers can earn 200% to over 1,000% margin on the generic version of a brand drug, but doctors may still prescribe the brand out of habit. Always ask if a generic is available - you’ll likely save 70-90%.

What’s causing drug shortages with generics?

Drug shortages happen when one factory can’t keep up - due to quality issues, equipment failure, or supply chain problems. Because generic makers operate on razor-thin margins, they often don’t have backup capacity. If a single plant shuts down, and there are only one or two other makers, shortages follow. That’s why the FDA is pushing for more manufacturers and better supply chain planning.

8 Comments

Let me break this down for you people who think generics are some kind of miracle - the FDA doesn’t care about your feelings, it cares about bioequivalence. That’s it. No magic, no conspiracy. Just math. And if you think China’s API supply is stable, you’ve never seen a factory shut down because the local government decided to ‘clean up the environment’ for a G20 summit. We’re one trade war away from insulin shortages becoming a national crisis. Wake up.

Thank you for this. I’ve been on lisinopril for 8 years and never realized I was saving $1,200 a year just by choosing the generic. 🙏 I told my mom last week to switch from Zyrtec to cetirizine - she cried because she thought the brand was ‘stronger’. It’s not. It’s just more expensive marketing. We need more posts like this ❤️

90% of prescriptions. 15.8% of spending. The math is undeniable. Pharma’s profit model is rent-seeking disguised as innovation.

Oh honey. You think this is bad? Wait till you find out the same company that makes Zyrtec also makes the generic - and charges the pharmacy 800% more for the brand version so they can pocket the difference while you're still paying $40 for a 30-day supply. It’s not a system. It’s a circus. And we’re all clowns buying the tickets.

I never knew the excipients mattered so much. I just thought generics were fake medicine. I’m sorry. I’ll ask for the generic next time. Also the part about automation saving costs? That’s wild. I never thought about pills being made by robots

This made me feel so much better about my meds. I’ve been paranoid about taking generics because I thought they were cheaper because they were worse. Turns out I’m just paying for a pretty label. Thanks for the clarity. 🌿

Okay but imagine if we applied this logic to everything. Like, why do we pay $15 for a plain t-shirt when the same one from the same factory costs $3 online? Why do we think medicine is different? It’s not. It’s just been sold to us as special. The real innovation isn’t the drug - it’s the system that lets millions afford it. We need to celebrate that, not ignore it. Someone’s life is literally cheaper than a Netflix subscription. That’s not broken. That’s beautiful.

Let’s be real - if you’re still taking brand-name drugs because you ‘trust them more’, you’re not being cautious. You’re being manipulated. The FDA’s standards are the same. The active ingredient is identical. The only difference is the logo on the bottle and the marketing budget that paid for your doctor’s lunch. Don’t be the person who pays extra because they’re scared of a white pill with no name on it. You’re not protecting your health - you’re protecting Big Pharma’s bottom line.

Write a comment